In industrial formulations, ingredient selection affects not only the functional performance of the final product but also manufacturing consistency, shelf stability, and regulatory compliance. Grape Seed Extract Powder 95% Proanthocyanidin UV has emerged as a standardized botanical ingredient widely used across nutraceuticals, functional beverages, personal care, and pet nutrition. Its high purity and standardized composition make it a reliable option for formulators and procurement teams aiming for consistent outcomes, easier blending, and predictable stability in dry and liquid matrices.

This article examines how this ingredient can improve formulation efficiency, provides insights into sourcing and compliance, and outlines best practices for bulk procurement in Canada.

What Makes Grape Seed Extract Powder 95% Proanthocyanidin UV Suitable for Industrial Formulations

Standardized 95% proanthocyanidin content ensures uniform functional properties, contributing to reproducible product performance and predictable processing behavior.

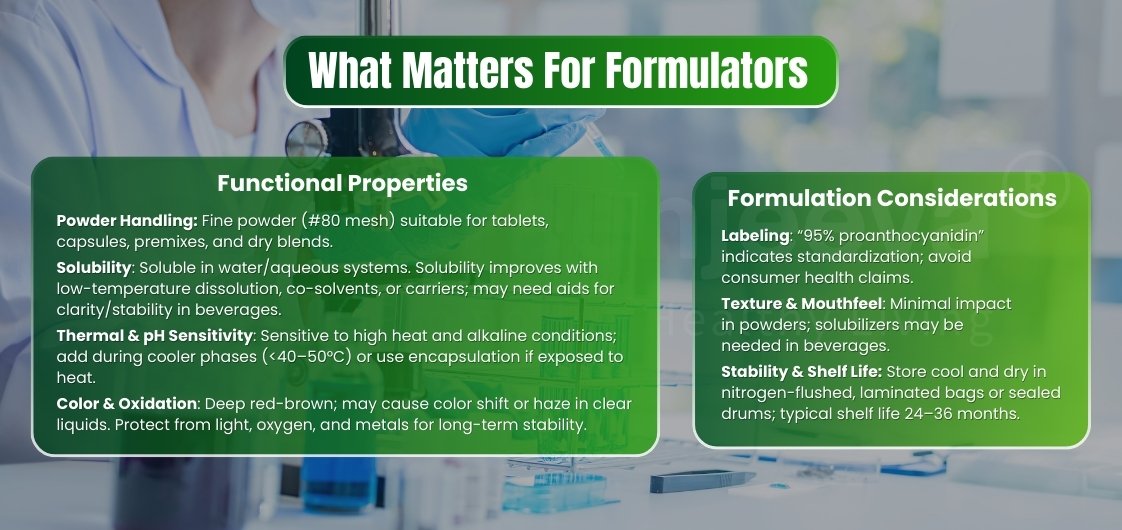

Grape Seed Extract Powder, standardized to 95% proanthocyanidins (OPCs), is derived from grape seeds separated during winemaking. The seeds undergo food-grade extraction methods, typically using ethanol-water systems, followed by concentration and drying. Some suppliers employ solvent-free or green extraction methods that are compatible with clean-label requirements. The final powder is a reddish-brown fine particle product, often passing through an 80-mesh screen, suitable for dry blending, encapsulation, and incorporation into beverages or topical systems.

Its high OPC content allows formulators to achieve predictable interactions with other ingredients. The powder’s moisture content, particle size, and flow properties directly influence tablet compression, capsule filling, and premix consistency. In liquid matrices, its solubility, pH stability, and color profile are key factors that affect clarity and stability, especially in functional beverages or emulsions.

How Can Bulk Grape Seed Extract Powder Be Integrated into Different Product Categories

Application flexibility across nutraceuticals, beverages, cosmetics, and pet nutrition allows for efficient use of bulk ingredient inventory in multiple manufacturing lines.

– Nutraceuticals and Dietary Supplements

Bulk Grape Seed Extract Powder is frequently used in capsule and tablet formulations. Standardized 95% OPC content simplifies dosing calculations, minimizes batch-to-batch variability, and improves compressibility in dry blends. Powder flow, particle size, and bulk density are critical parameters for R&D teams when designing direct compression or encapsulation lines.

– Functional Beverages

In powdered or ready-to-mix formulations, solubility and dispersion are primary considerations. The extract can be pre-dispersed in a small portion of liquid or incorporated using solubilizers or microencapsulation to reduce haze and sedimentation. pH and temperature sensitivity must be accounted for; adding the extract during cool-down stages helps maintain stability while integrating it efficiently into production workflows.

– Personal Care and Cosmetic Applications

In creams, serums, and lotions, the extract is added during cool-down phases to preserve its composition. Its inclusion typically ranges from 0.5% to 2% depending on formulation goals. Consistent particle size and solubility help achieve uniform distribution in emulsions, minimizing processing challenges and ensuring batch consistency.

– Pet Nutrition and Functional Feed

Formulators in pet food manufacturing benefit from standardized powder for dry blending in premium pet food or supplement chews. Uniform particle size and moisture levels support even distribution across the product matrix, simplifying automated blending and extrusion processes.

What Are the Key Considerations for Sourcing Bulk Grape Seed Extract Powder

Evaluating supplier credentials, product specifications, and compliance documentation ensures that bulk supply meets formulation and regulatory requirements.

When procuring Grape Seed Extract Powder in bulk, several technical and regulatory factors require attention:

– Certificate of Analysis (COA): Verify OPC content, moisture, ash, particle size, and bulk/tapped density. COAs should indicate the analytical method used (UV-vis, HPLC, or validated assay).

– Residual Solvents: Ethanol residues must meet food-grade specifications; solvent-free or green extraction methods offer additional clean-label assurance.

– Heavy Metals and Pesticides: Request ICP-MS testing for lead, cadmium, arsenic, and mercury, and pesticide screening for vineyard-derived residues.

– Microbiological Testing: Total plate count, yeast, mold, and coliforms should fall within acceptable ranges for food-grade or cosmetic applications.

– Certifications: Non-GMO, USDA Organic, Kosher, or Halal certificates may be required depending on product positioning.

– Packaging and Storage: Nitrogen-flushed, laminated bags or drums help maintain moisture and prevent oxidation. Storage at controlled temperature and humidity supports long-term stability.

MOQ, sampling, and documentation procedures also play a role in ensuring a smooth supply chain. Many suppliers offer sample packs for testing in pilot batches before committing to larger orders. Packaging specifications, lead times, and shelf-life data should be reviewed in advance to align with production planning.

How Do Formulators Ensure Consistent Quality Across Batches

Maintaining consistent performance requires monitoring particle size, moisture, assay results, and storage conditions across all incoming lots.

Standardization to 95% proanthocyanidins facilitates uniform functional performance, but batch-to-batch quality verification remains critical. Procurement teams should confirm:

– Identity Testing: HPLC or UV fingerprinting can verify OPC profile and detect potential adulteration with other tannin sources.

– Batch Matching: COA comparison across lots ensures consistent moisture, ash, and particle-size specifications.

– Process Integration: Solubility, dispersibility, and heat or pH sensitivity should be assessed for each incoming batch to maintain efficiency in production lines.

By combining rigorous QC with standardized specifications, R&D and production teams can minimize formulation variability, reduce rework, and streamline manufacturing processes.

What Market and Regulatory Factors Influence Grape Seed Extract Powder Sourcing in Canada

Understanding import, regulatory, and industrial demand trends enables informed procurement and supply planning.

Canada relies on imported Grape Seed Extract Powder due to limited domestic production. Key sourcing considerations include compliance with CFIA regulations for food ingredients, Health Canada guidelines for natural health products, and proper documentation for organic or non-GMO certifications.

Demand trends show growth across functional beverages, nutraceuticals, and pet nutrition segments. R&D efforts increasingly focus on microencapsulation, solubility enhancement, and integration into multi-ingredient formulations to improve process efficiency. Suppliers providing detailed COAs, traceability, and consistent supply can reduce production risks and streamline integration into multiple product categories.

Conclusion

Grape Seed Extract Powder 95% Proanthocyanidin UV offers standardized functional properties that simplify integration across multiple industrial applications. For formulators, R&D teams, and procurement managers, focusing on particle size, moisture content, solubility, and standardized OPC levels ensures predictable performance in tablets, beverages, creams, and pet nutrition products. Evaluating suppliers based on COA accuracy, certifications, heavy-metal testing, and storage conditions supports consistent quality and efficient manufacturing workflows.

For Canadian manufacturers and sourcing teams seeking reliable, clean-label Grape Seed Extract Powder, Green Jeeva provides bulk supply options with full documentation and traceability.

Contact Green Jeeva to discuss sample packs, bulk pricing, and technical support for integrating Grape Seed Extract Powder 95% Proanthocyanidin UV into your formulations.

Disclaimer: This article is intended for educational and industry insight purposes only. It does not provide medical advice or prescribe usage of ascorbic acid powder for health-related conditions.