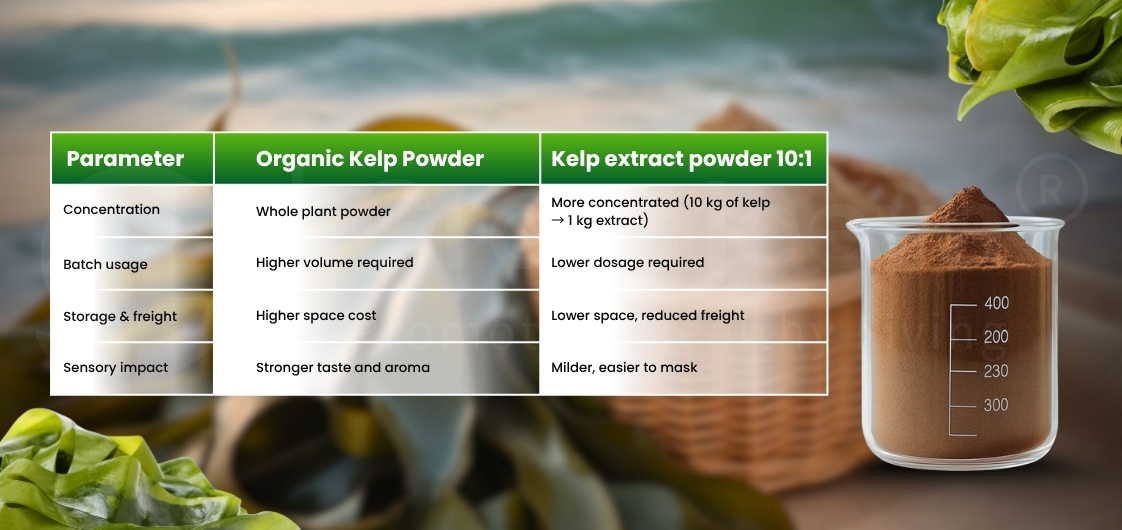

When procurement teams evaluate kelp ingredients, discussions often focus on price per kilogram. Yet price alone rarely reflects how the material performs during production. Factors such as dosage requirement, batch weight, dusting potential, equipment handling, and mixing efficiency all influence the true cost per finished unit.

Many manufacturers are shifting from Organic Kelp Powder—whole-plant milled powder—to Kelp Extract Powder, particularly Kelp extract powder 10:1, where 10 kilograms of raw kelp are concentrated into 1 kilogram of extract. The central question becomes:

Does a concentrated 10:1 extract reduce overall cost per finished unit, even if the raw material costs more per kilogram?

What makes Kelp Extract Powder different from Organic Kelp Powder?

Organic Kelp Powder is whole plant, retaining natural fiber content. It is commonly used in:

– Functional foods

– Clean-label seasoning blends

– Pet nutrition formulations

By contrast, Kelp Extract Powder is filtered and concentrated, with insoluble fractions removed during extraction.

Key differences and operational advantages of Kelp extract powder 10:1 include:

– Lower dosage requirement: Less material is needed to achieve the desired formulation effect.

– Reduced batch weight: Makes handling, weighing, and mixing simpler.

– Improved dispersion: Powder blends more consistently, especially in beverages and ready-to-mix formulations.

– Smaller capsule/tablet volumes: Reduced reliance on fillers to meet capsule or tablet weight.

While procurement teams may initially ask only about price per kilogram, formulation teams focus on questions such as:

– What is the cost per dosage and per finished unit?

– How much weight will this ingredient add to the batch?

– Will the ingredient create dusting or handling issues during scale-up?

These considerations often determine whether an extract or whole-plant powder is the better choice.

How does concentration affect manufacturing cost at scale?

The concentrated nature of Kelp Extract Powder 10:1 changes the economics of large-scale production:

– Reduced material usage: Roughly one-tenth of the amount required with whole-plant powder.

– Lower handling time: Smaller batches are faster to weigh and mix.

– Minimized material loss: Less dusting and waste during bag handling.

– Optimized storage and freight: Reduced bulk volume saves warehouse space and shipping costs.

When producing batches of 500–2,000 kg, these operational efficiencies compound, resulting in measurable cost savings. Even if the price per kilogram of extract is higher, its reduced dosage often makes it more cost-effective on a per-batch or per-serving basis.

Where is Kelp Extract Powder used in industrial formulations?

Kelp Extract Powder is versatile across multiple industries where precision, dosing, and handling efficiency are important:

– Nutraceuticals: Capsules, tablets, and powdered blends; concentrated extract ensures consistent dosing and smaller dosage size.

– Functional beverages: Mixes cleanly with reduced sediment, offering more uniform dispersion.

– Personal care and cosmetics: Supports viscosity and texture consistency in water-based formulations while maintaining clean-label appeal.

– Pet nutrition and feed: Contributes natural mineral content and flavor identity.

– Seasoning and gourmet blends: Adds mild salt-associated taste profile and functional bulk.

Formulators generally choose Kelp Extract Powder for precision and efficiency, while Organic Kelp Powder is selected when whole-food identity and fiber content are priorities.

What should procurement teams verify before bulk purchasing?

Before sourcing Bulk Organic Kelp Powder or Kelp Extract Powder 10:1, procurement and quality teams should ensure the following:

– Documentation: Batch-level COA including assay, moisture, particle size, and microbiology.

– Contaminants: Heavy metals testing (arsenic, mercury, cadmium, lead) and pesticide residue reports.

– Traceability: Harvest origin documentation to confirm responsible sourcing.

– Allergen & GMO declarations: Compliance with market requirements.

– Organic compliance: USDA Certified Organic Kelp Powder certificate must list the exact SKU, not just the facility.

R&D teams often request small samples (100–500 grams) to evaluate performance in pilot batches. They also consider:

– Solubility and particle size

– Moisture content

– Flow properties for equipment compatibility

These steps help avoid scale-up issues and ensure batch consistency.

Does organic certification influence buying decisions?

Organic certification is increasingly important for clean-label product lines. Any product carrying the organic logo must source all botanical ingredients from suppliers certified under accredited programs such as USDA NOP.

Key points to consider:

– Certification applies even at low inclusion rates (1–2%).

– Working with a verified Organic Kelp Powder Supplier ensures traceability from harvest to finished product.

– Organic compliance reduces audit risks and aligns with regulatory expectations in Canada and the U.S.

Conclusion

Switching to Kelp Extract Powder, especially Kelp extract powder 10:1, is primarily a manufacturing efficiency decision rather than a marketing one. Extracts reduce batch weight, improve dosing precision, simplify handling, and lower storage and transport burdens, often resulting in lower cost per unit at scale.

Whole-plant powders remain relevant when volume and food identity matter. Extracts are better suited for large-scale operations where precision, efficiency, and handling economics are the priority.

For procurement or R&D teams evaluating bulk Kelp Extract Powder 10:1, Green Jeeva provides:

– Free samples for testing and pilot runs

– Certificates ready for audits

Request a quote today!

**The Food and Drug Administration has not evaluated these statements. This product is not intended to diagnose, treat, cure, or prevent any disease.**