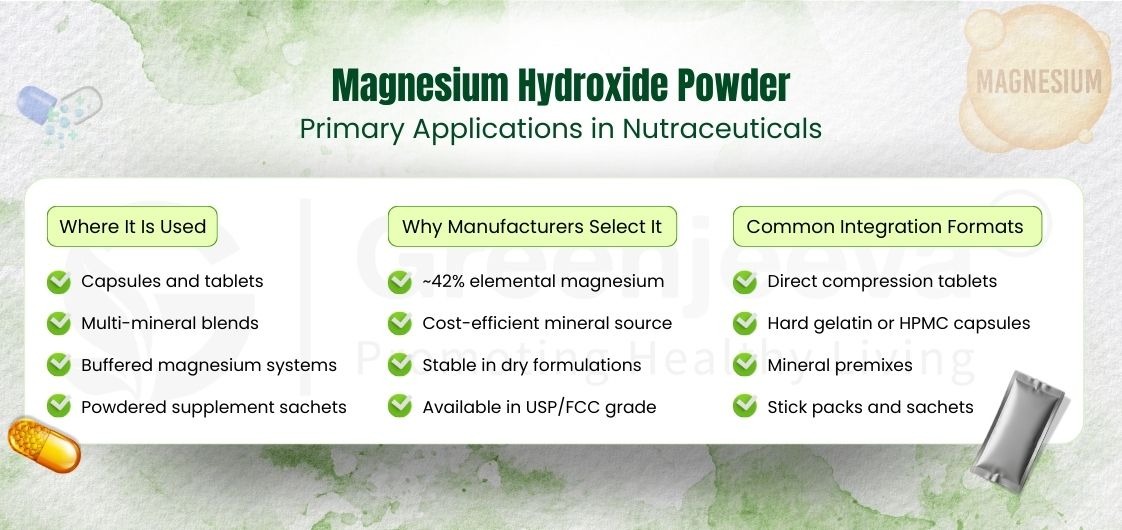

Magnesium selection is rarely a simple cost comparison. For R&D teams working on tablets, capsules, mineral blends, and premixes, the decision between magnesium hydroxide powder and magnesium oxide often comes down to reactivity, elemental concentration, processing behavior, and compliance requirements.

Both compounds are widely used in solid dosage formats. However, differences in alkalinity profile, assay standards, and formulation performance can significantly impact manufacturing efficiency and product consistency.

This article outlines when magnesium hydroxide is the more suitable option and how procurement teams can evaluate it from a technical and sourcing standpoint.

What Is the Difference Between Magnesium Hydroxide and Magnesium Oxide

Magnesium hydroxide (Mg(OH)₂) is less reactive, provides controlled alkalinity, and contains ~41–42% elemental magnesium, while magnesium oxide (MgO) contains ~60% elemental magnesium and is more reactive.

Composition and Elemental Content

-

Magnesium hydroxide powder

-

• Chemical formula: Mg(OH)₂

-

• Elemental magnesium: ~41–42%

-

• USP assay range (dried basis): 98.0%–102.0%

-

• Loss on ignition: 30.0%–33.0%

-

-

Magnesium oxide

-

• Chemical formula: MgO

-

• Elemental magnesium: ~60%

-

• Higher alkalinity and faster reactivity

-

While magnesium oxide offers higher elemental magnesium per gram, magnesium hydroxide provides more controlled pH behavior and lower reactivity during blending and compression.

When Is Magnesium Hydroxide Preferred in Solid Dosage Formulations

R&D teams select magnesium hydroxide when they need moderate alkalinity, better processing stability, and controlled reactivity in tablets or capsules.

Controlled Alkalinity

Magnesium hydroxide has limited solubility in water and produces a suspension pH of approximately 10–10.5. Compared to magnesium oxide, it reacts more gradually with acids. This slower interaction can support:

-

• Reduced risk of rapid pH spikes

-

• Improved compatibility in multi-mineral blends

-

• Better control during effervescent system development

For direct compression tablets, this reduced aggressiveness can help minimize unwanted interaction with sensitive excipients.

Moisture and Processing Stability

Magnesium hydroxide is generally less hygroscopic than some alternative magnesium salts. For manufacturing teams, that translates to:

-

• Improved powder flow in dry blending

-

• Lower risk of moisture-driven clumping

-

• Better long-term storage stability in bulk packaging

These characteristics become relevant in high-speed tableting lines and capsule-filling operations.

How Does the Magnesium Hydroxide Manufacturing Process Affect Quality

The manufacturing route determines purity, heavy metal levels, particle size distribution, and consistency.

There are two primary production methods:

-

1. Seawater or Brine Precipitation

Magnesium-rich seawater or brine is reacted with calcium hydroxide to precipitate magnesium hydroxide. The material is then filtered, washed, dried, and milled.

Quality considerations include:

-

• Removal of soluble salts (USP limit: NMT 2.0%)

-

• Carbonate control

-

• Controlled drying to meet loss on drying limits (NMT 10.0% w/w)

-

2. Mined Brucite Processing

Naturally occurring brucite is crushed, purified, and milled. This method can offer higher natural magnesium hydroxide content but requires careful heavy metal screening.

For supplement-grade material, the following specifications are commonly evaluated:

-

• Assay (dried at 105°C for 2 hours): 98.0%–102.0%

-

• Limit of calcium: NMT 1.5%

-

• Total heavy metals: NMT 10 ppm

-

• Lead: NMT 1.5 ppm

-

• Arsenic: NMT 3 ppm

-

• Mercury: NMT 1 ppm

-

• Cadmium: NMT 2 ppm

Compliance with USP <231> and <232> heavy metal standards is often required.

Magnesium Hydroxide vs Magnesium Oxide in Tablet Compression

Magnesium hydroxide may provide smoother compression behavior in formulations sensitive to high alkalinity.

Magnesium oxide is highly reactive and alkaline. In certain blends, that reactivity can affect:

-

• Binder interaction

-

• Disintegration timing

-

• Excipient stability

Magnesium hydroxide, due to its moderate reactivity, can support:

-

• More predictable compression

-

• Reduced risk of excipient discoloration

-

• Balanced mineral loading in multi-ingredient systems

However, R&D teams must factor in the lower elemental magnesium percentage when calculating label declarations and tablet weight.

Is Magnesium Hydroxide Suitable for Animal Nutrition Applications

Yes, magnesium hydroxide powder for animal nutrition is used in mineral premixes and dry feed blends where controlled alkalinity is required.

In feed and pet supplement formulations, magnesium hydroxide can function as:

-

• A mineral source in dry premixes

-

• A buffering component in formulated feeds

-

• A stabilizing alkaline compound in powder blends

Key considerations for animal nutrition applications include:

-

• Particle size consistency

-

• Absence of contaminants

-

• Verified heavy metal testing

-

• Proper documentation for feed compliance

Procurement teams should confirm whether the grade supplied aligns with feed or supplement specifications, as requirements differ from human supplement standards.

What Should Buyers Check When Sourcing Magnesium Hydroxide Wholesale

Review assay, heavy metal compliance, particle size distribution, and documentation before confirming bulk orders.

For magnesium hydroxide wholesale procurement, buyers typically request:

Technical Documentation

-

• Certificate of Analysis (batch-specific)

-

• Safety Data Sheet

-

• Technical Data Sheet

-

• Allergen statement

-

• Country of origin declaration

Specification Checks

-

• Assay range 98.0%–102.0%

-

• Loss on drying NMT 10.0%

-

• Soluble salts NMT 2.0%

-

• Heavy metals within defined ppm limits

Operational Considerations

-

• MOQ for bulk orders

-

• U.S. stock availability

-

• Lead time confirmation

-

• Packaging format (25 kg bags, super sacks)

For Canadian buyers local stock availability and fast lead time can reduce production downtime and support faster inventory turnover.

How Does Elemental Magnesium Content Influence Formulation Decisions

Magnesium oxide offers higher elemental density, but magnesium hydroxide offers greater control in sensitive blends.

Because magnesium oxide contains roughly 60% elemental magnesium compared to ~42% in magnesium hydroxide, it allows lower inclusion rates per serving. However, higher elemental concentration does not always equal better formulation performance.

R&D teams often weigh:

-

• Label weight constraints

-

• Tablet size limitations

-

• Interaction risk with other minerals

-

• Required buffering behavior

In cases where reactivity control and compliance precision matter more than elemental density, magnesium hydroxide becomes a practical choice.

Also read: Magnesium Hydroxide Powder: The Essential Ingredient Shaping Eco-Friendly Natural Deodorants

Conclusion

Choosing between magnesium hydroxide and magnesium oxide is a technical decision shaped by formulation objectives, compliance thresholds, and processing conditions.

Magnesium hydroxide powder offers:

-

• Controlled alkalinity

-

• Moderate elemental magnesium content (~42%)

-

• USP-aligned purity range (98.0%–102.0%)

-

• Defined heavy metal limits

-

• Compatibility in solid dosage and animal nutrition applications

For R&D and procurement teams working within structured compliance frameworks, these characteristics support stable production planning and consistent batch performance.

At Green Jeeva, magnesium hydroxide powder is available from our local Canada warehouse with faster shipment options, and a zero-question-asked return policy. Detailed COA documentation and technical specifications are available upon request to support your sourcing evaluation.

If your team is comparing magnesium hydroxide vs magnesium oxide for an upcoming formulation, request technical documents or a free sample to assess compatibility within your system before scaling to bulk production.

**The Food and Drug Administration has not evaluated these statements. This product is not intended to diagnose, treat, cure, or prevent any disease.**