-

Toll Free : +1(866)532-3512Toll Free : +1(866)532-3512

-

enquiry@greenjeeva.caenquiry@greenjeeva.ca

-

WhatsApp

At Green Jeeva Canada, our Research and Development (R&D) department is at the forefront of nutraceutical innovation. We’re dedicated to creating health solutions that not only meet global wellness trends but also ensure efficacy, safety, and sustainability. Our state-of-the-art facilities and skilled team drive this mission, pushing the boundaries of what’s possible in the world of dietary supplements.

Our R&D center utilizes cutting-edge technologies to ensure top-tier product development and quality control:

We specialize in creating innovative product formulations that are tailored to specific health objectives and market needs.

Ensuring product safety and adherence to regulations through comprehensive microbial testing. We also support our customers with microbiological testing, aligning with Certificate of Analysis (COA) parameters.

We offer precise identification of bioactive compounds and provide support for herbal product testing and quality validation.

Delivering comprehensive analytical solutions for evaluating various parameters outlined in the COA, which ensures consistent quality and reliability.

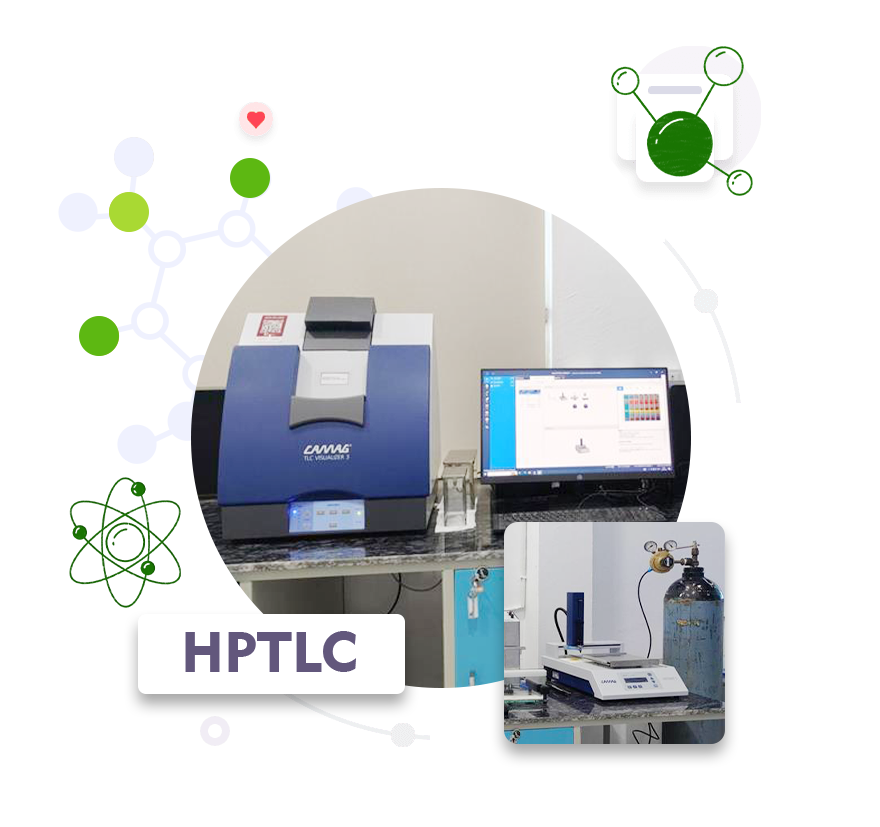

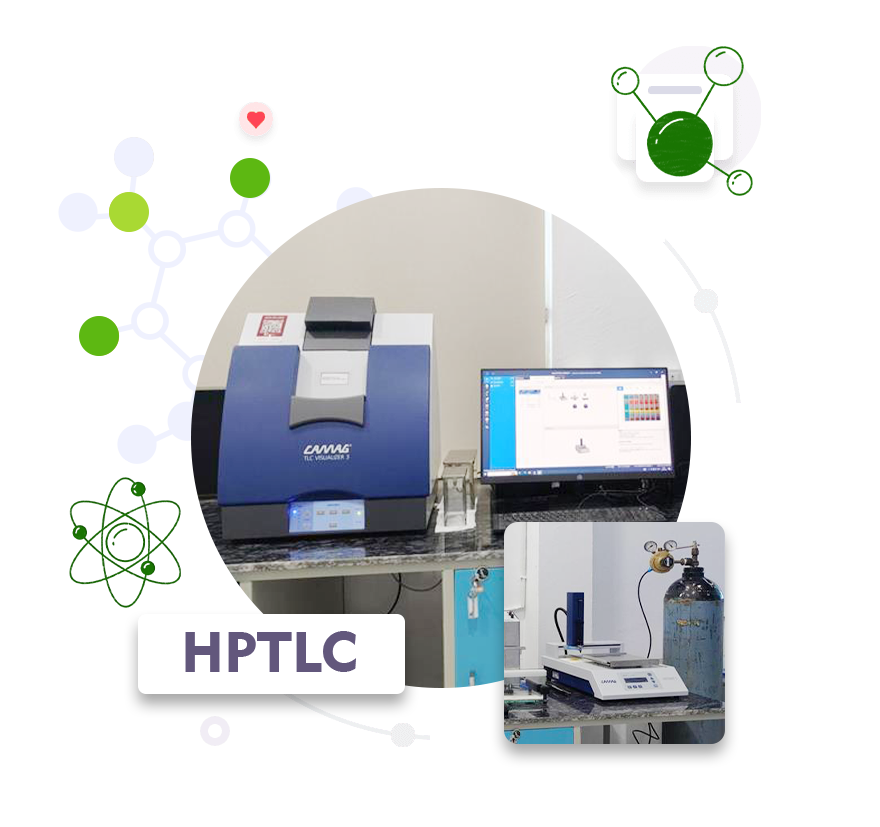

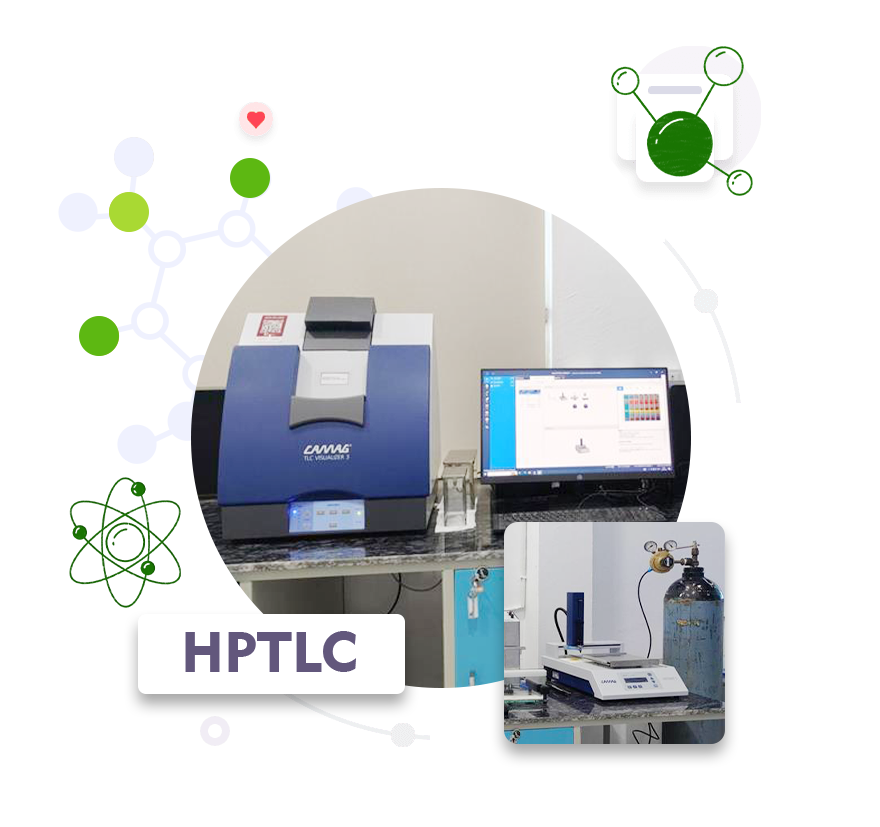

High-Performance Thin-Layer Chromatography (HPTLC) is a sophisticated analytical technique used to separate and identify compounds based on their varying affinities toward a stationary phase (e.g., silica gel) and a liquid mobile phase. As the mobile phase moves upward on the plate, analytes migrate at different rates, forming distinct spots that facilitate their identification and quantification.

HPTLC is widely utilized across pharmaceuticals, nutraceuticals, herbal formulations, and natural product analysis. It plays a crucial role in identification testing, purity assessment, stability studies, and fingerprint profiling. Known for its efficiency, cost-effectiveness, and capability to analyze multiple samples simultaneously, HPTLC is an indispensable tool in research, quality control, and standardization processes.

A UV-Vis Spectrophotometer is a crucial analytical instrument used to measure the absorbance or transmittance of a substance in the ultraviolet (UV) and visible (Vis) regions of the electromagnetic spectrum, typically ranging from 200 to 800 nm. It operates on the principle that molecules absorb light at specific wavelengths, corresponding to electronic transitions within their structure. By analyzing absorption spectra, this technique enables precise identification and quantification of compounds.

Widely utilized in pharmaceuticals, nutraceuticals, environmental analysis, and biochemistry, UV-Vis spectrophotometry plays a key role in concentration determination, purity testing, and kinetic studies. Its accuracy, simplicity, and versatility make it an indispensable tool in research, quality control, and analytical laboratories.

An autoclave is a vital sterilization device designed to eliminate microorganisms—including bacteria, viruses, and spores—from laboratory equipment, culture media, and biological waste. It operates on the principle of moist heat sterilization, using high-pressure steam at temperatures typically ranging from 121°C to 134°C. This intense combination of heat, steam, and pressure effectively denatures microbial proteins and disrupts cellular structures, ensuring complete sterilization.An autoclave is a vital sterilization device designed to eliminate microorganisms—including bacteria, viruses, and spores—from laboratory equipment, culture media, and biological waste. It operates on the principle of moist heat sterilization, using high-pressure steam at temperatures typically ranging from 121°C to 134°C. This intense combination of heat, steam, and pressure effectively denatures microbial proteins and disrupts cellular structures, ensuring complete sterilization.

Autoclaves are indispensable in laboratories, healthcare facilities, and industrial settings, playing a crucial role in maintaining aseptic conditions, preventing contamination, and ensuring compliance with sterilization standards. Known for their efficiency, reliability, and environmentally friendly operation, autoclaves are a cornerstone of modern scientific, medical, and industrial hygiene practices.

A laminar airflow (LAF) unit is an essential laboratory device designed to create a sterile, particle-free working environment by directing uniform airflow through a high-efficiency particulate air (HEPA) filter. Operating on the principle of unidirectional airflow—either horizontal or vertical—it minimizes turbulence and effectively sweeps away airborne contaminants, preventing cross-contamination.

LAF units are widely utilized in microbiology, tissue culture, pharmaceutical, and electronics industries to ensure aseptic conditions for sensitive processes. Their ability to maintain a controlled, contaminant-free workspace makes them indispensable for quality assurance, research integrity, and regulatory compliance in scientific and industrial settings.

Laboratory incubators are essential devices that create a controlled environment for the growth and maintenance of microorganisms, cells, and tissues. They regulate critical parameters such as temperature, humidity, and, in some cases, CO₂ levels to simulate optimal growth conditions with precision.

Widely used in microbiology, cell culture, pharmaceutical research, and clinical diagnostics, incubators support applications such as bacterial culture, fermentation, and the storage of biological samples. Their reliability in maintaining stable conditions makes them indispensable for research, quality control, and production processes across various scientific and industrial fields.

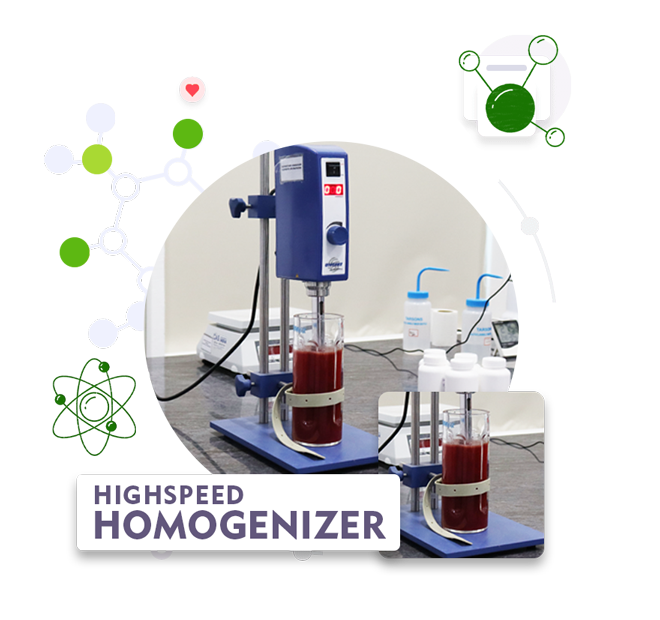

A high-speed homogenizer is a powerful laboratory device designed to efficiently mix, emulsify, and homogenize liquid and semi-solid samples. It operates on the principle of mechanical shear forces, generated by a rapidly rotating rotor within a stationary stator, to break down particles, disrupt cell structures, and ensure uniform dispersion of components.

Widely utilized in the pharmaceutical, nutraceutical, biotechnology, and food industries, high-speed homogenizers play a crucial role in sample preparation, formulation development, and emulsification. Their precision, versatility, and ability to process a wide range of sample viscosities make them indispensable for achieving consistency, reproducibility, and high-quality results in both research and production settings.

A stability chamber is a specialized laboratory device engineered to simulate and maintain controlled environmental conditions—such as temperature, humidity, and light—to evaluate the stability and shelf life of products. By providing precise and consistent settings, it replicates real-world storage and climatic conditions, allowing researchers to assess how pharmaceuticals, nutraceuticals, cosmetics, and food products degrade over time.

Stability chambers play a critical role in regulatory compliance, quality assurance, and product development, helping determine packaging requirements, expiration dates, and optimal storage conditions. Their accuracy, reliability, and ability to generate reproducible data make them indispensable for stability testing across various industries.

© 2025 Greenjeeva CA . All Rights Reserved.